James Coffee Studios

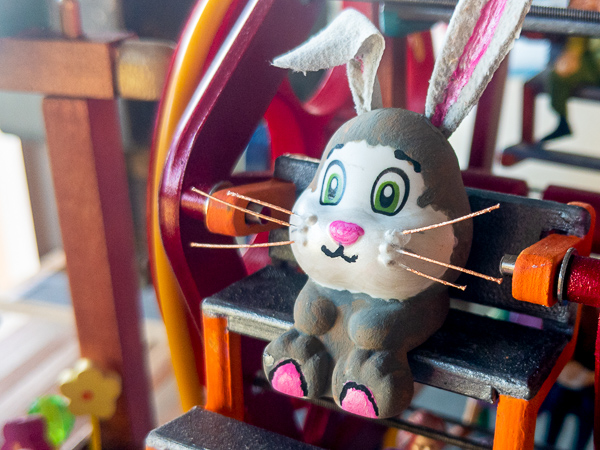

(March 23, 2024, Escondido, California) James Coffee Studios is focused on performance automata. At this time the performance automata is in the form of a 20-pipe street organ that is festooned with a mini-carnival and musicians. No automata are offered for sale, although commissions are considered.

AUTOMATA

There is a strong focus on automata at James Coffee Studios. Jim designs and creates automata in his studio. At this time he is focused on creating ‘performance automata’.

photography

I have photographed intensely in Gold Beach, Oregon, and San Diego, California. Because technology is changing I no longer provide online image catalogs. If you have an interest in an image(s) that you think I might have please don’t hesitate to contact me.

WOODEN NAME TAGS

James Coffee Studios no longer creates wooden name tags. We are pleased to refer you to Colorado Heirloom for your laser-engraved wood needs.